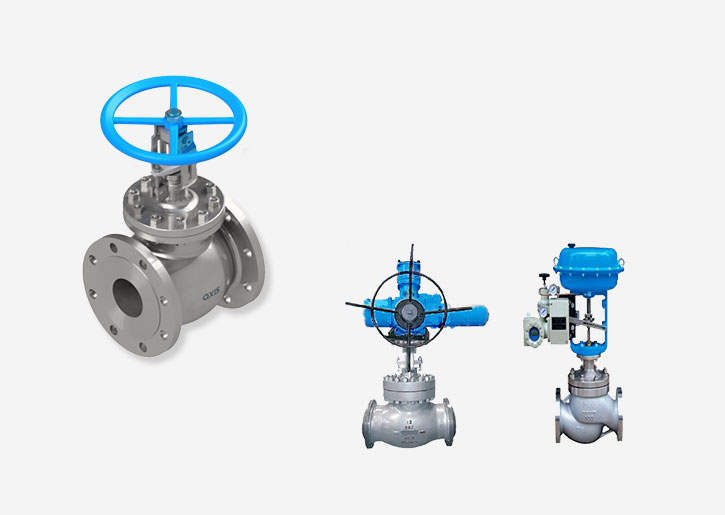

Globe Valve

All Globe valves utilize the "port closure" concept of valves. This means that fluid passes through a specific opening (rather than a lateral passageway, as in the case of gate valves), and the fluid is controlled by a stem-mounted disc or inserted plug in that area. Despite lacking the straight, unobstructed passageway of the gate valve, these Globe types are superior in two key aspects: throttling and serviceability under frequent use. They are better at the throttling function because they permit fluid to exit uniformly around the circumference of a seat, rather than "slicing" down to limit passage through a narrowly restricted area. The valve size is available in DN15 to DN900 and #150, #300, #600, #800, #900, #1500 and #2500 pressure ratings with flanged ends.

- Mirror-finished stainless steel stem.

- Fine-grained metal seats.

- High integrity stem sealing.

- Blowout-proof stem.

- Bi-directional valve with tight shut of f sealing capability.

- Adaptability to fit between companion flanges of all popular flange standards.

- The valve can be supplied with matching pneumatic actuator operated along with other accessories such as limit switches, positioners etc., to form a complete flow control system.

Design Features

| Design Standards | ASME B16.34 / API 623 / API 602 / BS 1873 |

|---|---|

| Size Range | DN 15 to DN 900 [l /2" to 36"] |

| Pressure Rating | #150 / #300 / #600 I #800 I #900 I #1500 / #2500 |

| Construction Type | Rising Stem & Non Rising Stem |

| Design Features | Bolted Bonnet, OS&Y Type |

| Operator Type | Hand Wheel, Gear, Electrical Actuator & Pneumatic Actuator |

| Face to Face Standard | ASME B16.10 / ISO 5752 / BS EN 558 |

| End Connection | Flanged End, Bull Weld End, Socket Weld & Screwed End |

| Testing Standard | API 598 / BS EN 12266-1 / BS 6755-1 |

| Top Mountain Flange | ISO 5211 |

Materials

- Carbon Steel/ Stainless Steel / Duplex Stainless Steel/ Super Duplex Stainless Steel/ Aluminum Bronze